- Soil Vault Systems

- Root Management

- Tree Pit Irrigation and Aeration

- Tree Protection

- Tree Guying

- Green Wall Systems

- All Products

Download our latest Specifier Update

Stratavault

Grow Better Quality Trees with Stratavault

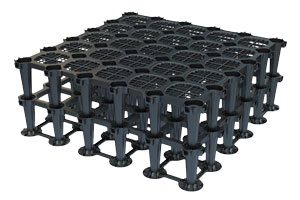

Stratavault™ represents the sixth generation of structural soil cells and has been developed and patented globally by the top soil cell supplier Citygreen®. Stratavault builds on the experience gained through trials, projects, and collaborations with industry innovators. The main drivers have been the need for lower installation costs, higher strength, reduced transport costs, and maintenance of large spaces for root growth and service integration.

Benefits

- Modules assemble to form an interconnected matrix, so applied loads are shared and lateral strength maximized.

- Increased apertures permit larger conduits, service pipes and aeration systems

- Made from 100% recycled polymers; ensuring maximum environmental benefit & ‘Green Building’ contribution

- Modules ‘snap-together’ incredibly fast, providing super-efficient assembly time on site (records show it takes approx 2 mins/m³!)

- No zip ties, screws or ground spikes required to fasten this system together; again providing super-fast and ‘hassle free’ assembly on site.

- Made in strategic locations in North America and Australia; supporting local industries and complying with green building requirements.

- Modules are designed to nest, giving significant volume reduction, and minimising shipping costs.

- No steel components required for strength; therefore nothing to rust or corrode

- Continuous physical laboratory tests of strength are conducted to ensure integrity of modules and quality assurance. Whilst FEA testing (Finite Element Analysis) is great during the design stages, we prefer to go by real life static and cyclic load testing in laboratories.

Download the Citygreen Stratavault Technical Document

Citygreen Stratavault PDF Download

"*" indicates required fields

Quick Efficient Assembly

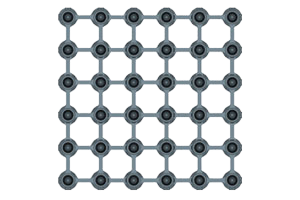

Stratavault is designed to achieve major reductions in installation costs. Units snap together quickly and easily, drastically reducing labor times. Positive and secure connectors are a feature of the Stratavault patented design both vertically and laterally. Stratavault components are simple and fast to click together, producing a strong integrated matrix.

Stratavault is designed to achieve major reductions in installation costs. Units snap together quickly and easily, drastically reducing labor times. Positive and secure connectors are a feature of the Stratavault patented design both vertically and laterally. Stratavault components are simple and fast to click together, producing a strong integrated matrix.

Save Cost on Freight

Another unique design feature of the Stratavault system is the significant volume reduction for freight. With increasing scrutiny placed on use of fossil fuels and shipping costs, it was decided that this unit must achieve major volume reductions for shipping. The innovative nesting design is protected by worldwide patents and design registration, as are all other design features.

Engineered Design with 100% Recycled Material

The Stratavault is a highly engineered system that owes much of its incredible strength to a unique design (subject to numerous patents).

Due to the emphasis Citygreen places on environmentally sustainable systems, over 700,000kg/700Tonne of plastic are saved from landfill every year.

Ultimate, Proven Strength Under Load

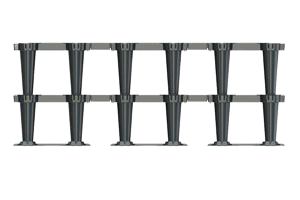

Due to ever increasing demands upon designers and planners, to incorporate green infrastructure beneath paved surfaces – Citygreen began developing further options for car parks and roadways. Today, the Stratavault is available in the popular ’30 series’ with 300kpa/43.5psi Ultimate Load capacity – and also in a ’45 series’ with 450kpa/65.2psi Ultimate Load capacity.

Due to ever increasing demands upon designers and planners, to incorporate green infrastructure beneath paved surfaces – Citygreen began developing further options for car parks and roadways. Today, the Stratavault is available in the popular ’30 series’ with 300kpa/43.5psi Ultimate Load capacity – and also in a ’45 series’ with 450kpa/65.2psi Ultimate Load capacity.

This physical load testing is part of an ongoing development and research program, and is the only true measure of structural integrity. Stratavault modules are made using 100% recycled resin, and have the highest structural integrity of any large soil cell.

Energy Use

The use of virgin resins in a product for the Green Building Industry has never been a part of the Stratavault development program. Virgin plastics have an unacceptably high level of embodied energy, whereas recycling waste plastic into an engineering grade product starts with a clean sheet as recognized by industry and the Green Building Council.

A Sustainable Solution for Transforming Grey Cities to Green

Cool cities with healthy, tree canopies while maintaining infrastructure integrity in any urban space.

Citygreen Stratavault™ revolutionises tree planting projects in city environments by maximising the soil volume available for tree roots, while also providing a stable base for roads, pavement and other installations.

With modules assembled in the form of a robust, interconnected matrix, Citygreen Stratavault™ offers easy installation and the flexibility to enable city trees to thrive even in difficult environments, producing environmental, economic and health benefits for all stakeholders.

Cool Your Cities Faster with Tree Canopy.

Book a Discovery Workshop

The World’s Most Superior Soil Cell

Citygreen Stratavault™ is the most sustainable, highly engineered large soil cell designed to install easily under sidewalks and parking lots, enabling trees to accept, store and transmit water, stormwater, nutrients and energy, while giving roots sufficient room to propagate.

Its unique matrix design and high-strength modules can also handle significant vehicular loads and traffic, preventing sidewalks, roads and buildings from damaged by long-term root growth.

The innovative nesting design of Citygreen Stratavault™ reduces freight and implementation costs. Its apertures are large enough to incorporate common conduits, service pipes and aeration systems within the structure.

Citygreen Stratavault™ is made from recycled and reused plastics yet offers the highest durability rating, offering a practical structural soil cell that also promotes sustainability.

![]()

Quick Assembly

The units of Citygreen Stratavault™ snap together easily. You don’t need zip ties, screws or ground spikes to fasten them together, reducing installation challenges.

![]()

Engineered Strength

Due its positive lateral and vertical connectors, an assembled Citygreen Stratavault™ matrix is considered the ultimate load bearing “root cell” structure.

![]()

Quality Control

Stratavault™ modules are crush tested during manufacture as part of the rigorous quality control standards required by Citygreen.

![]()

Reduced Energy Use

Virgin plastics have an unacceptably high level of embodied energy, which is why we don’t use new or single-use plastics for the production of Stratavault™.

Get Piece of Mind with 20 Years Warranty.

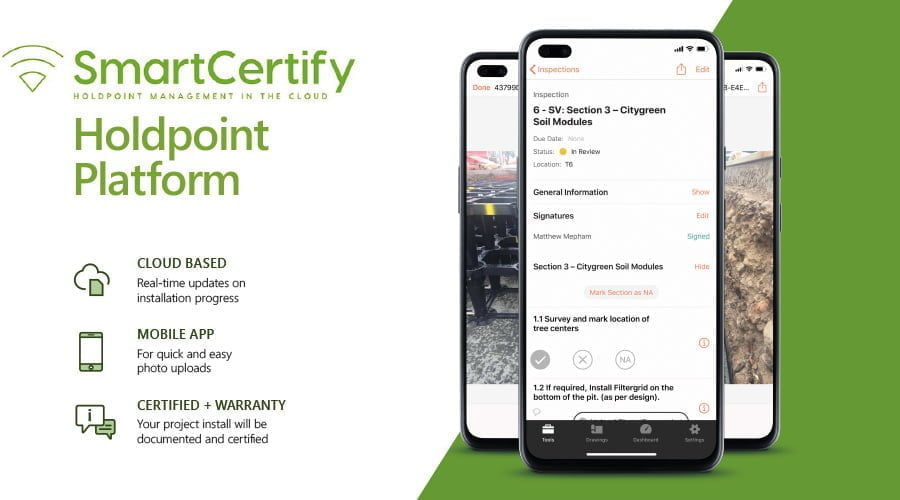

The SmartCertify hold point platform was developed to streamline the compliance element of Citygreen’s soil cell projects, through customization of advanced cloud smart technology. Enabling the installation team to watch videos for further understanding and snap progress photos using their smartphone or tablet, at set hold points throughout construction, to be uploaded in real-time to the cloud. Allowing Citygreen’s technical team, as well as other project partners, real-time updates on installation progress.

Product Specification

| Product | Description | Height per layer | Material | Ultimate Load Capacity |

|---|---|---|---|---|

| Stratavault 30 | High strength structural vault system | 400mm/16″ nom | 100% recycled PP | 300kpa/43.5psi |

| Stratavault 45 | Ultra high strength structural vault system | 400mm/16″ nom | 100% recycled ABS | 450kpa/65.2psi |

*Note: Product dimensions may change without notice. Please confirm with Citygreen at time of order placement. Download Technical Sheet Download Inspection, Maintenance & Repair Manual Access our Platinum Area for CAD library, construction details and product videos

The Stakeholders We Support

We help Urban Foresters & Arborists

By using Citygreen Stratavault™, you can create tree canopies 3x faster, addressing climate change through the healthy growth of urban trees.

We help Landscape Architects & Urban Planners

Stratavault™ can aid you in developing beautiful, greener spaces to make cities more liveable, healthier and sustainable than ever.

We help Civil Engineers

Citygreen StratavaultTM can help you find the perfect balance between the need for healthy, city trees and the requirements for preserving vehicle roads and pedestrian pavements.

The Benefits We Offer

- 30+ years of relevant project experience

- Global expertise from a proactive local team

- Sustainability driven and innovative tree planting solutions

- Real time updates for construction progress

- Expert technical coordination and project management

- Locally made products

- 20+ year warranties over all installed Citygreen systems

Case Studies

Award-winning Green Square Library and Plaza fuses built form and landscape

Constitution Avenue transformed into Canberra’s premier address

Innovative soil trench with water harvesting, for healthy trees in upgraded Macquarie Mall – using Stratavault

Enquire Online

Citygreen StratavaultTM ensures the success of urban tree growth. As a structural load bearing soil system, it enables tree roots to propagate without causing damage to the surfaces above. With Citygreen StratavaultTM, you can revive the beauty of cities with thriving tree canopies.

For more information simply fill out the form below and our team will contact you shortly.

Enquire Online

CitygreenTM Living Wall systems create healthy vertical gardens in urban infrastructures, making cities more visually appealing, sustainable and liveable for all. For more information simply fill out the form below and our team will contact you shortly.CONTACT FORM WIDGET TO BE INCLUDED IN

About Citygreen

For years, Citygreen has invested in comprehensive research and development to explore the challenges, the causes of failure and the reasons for the premature mortality of urban trees in city environments.

Today, our urban landscape products and services are considered the top benchmark in their corresponding fields – being endorsed by professional organisations around the world and placing Citygreen at the cutting edge of sustainable landscape solutions for cities globally.

Citygreen actively contributes to a world where sustainable green spaces are within reach of every person, every day.

Product Specification

| Product | Description | Height per layer | Material | Ultimate Load Capacity |

|---|---|---|---|---|

| Stratavault 30 | High strength structural vault system | 400mm/16″ nom | 100% recycled PP | 300kpa/43.5psi |

| Stratavault 45 | Ultra high strength structural vault system | 400mm/16″ nom | 100% recycled ABS | 450kpa/65.2psi |

*Note: Product dimensions may change without notice. Please confirm with Citygreen at time of order placement.

Download Technical Sheet

Download Inspection, Maintenance & Repair Manual

Download Stratavault Product Brochure

Access our Platinum Area for CAD library, construction details and product videos

“Great customer service, quick response times and a very in depth QA system with constant support.”

- Laura Wiesenekker, Project Engineer, Densford Civil -

“Citygreen is a very professional business, and I found everything was great in terms of deliveries, product supply and information. It was all forthcoming and helped us to complete the project.”

- Keith Burns, Architect/Designer, Keith Burns Architect -

“Citygreen offered training and invaluable technical assistance during the works.”

- James Callan, Estimating Manager, Complex Co Pty Ltd -

“Our experience, in working with a Citygreen Design Studio was second to none. We found responses from the design studio to be very timely, and technically thorough. We went backwards and forwards a number of times, looking at different iterations of the design and, nothing was too much trouble to examine and explore different possibilities. I would highly recommend the Citygreen Design Studio to any future client considering using your services.”

- Sandra Smith, Principal Landscape Architect, City Of Monash -

“We are big on compliance on all projects, and the fact that their SmartCertify cloud platform covers all bases, and supports their 20 year warranties, is critical – especially that these pits are being installed under roadways and footpaths.”

- Johny Purkaystha, Civil Program Engineer, Central Coast Council -

"I reviewed all the previous projects that we have installed in the past couple years using your product and I can happily report back that we have 0% mortality in the soil cells, which is incredible!"

- Brendan Wilton, CEO, Trim Landscaping, Bedford, Canada -